Stemmed largely from their solid background in environmental engineering, industrial design and safety/health management, GreenEcoPro’s cleaning solutions are must-haves in any factory.

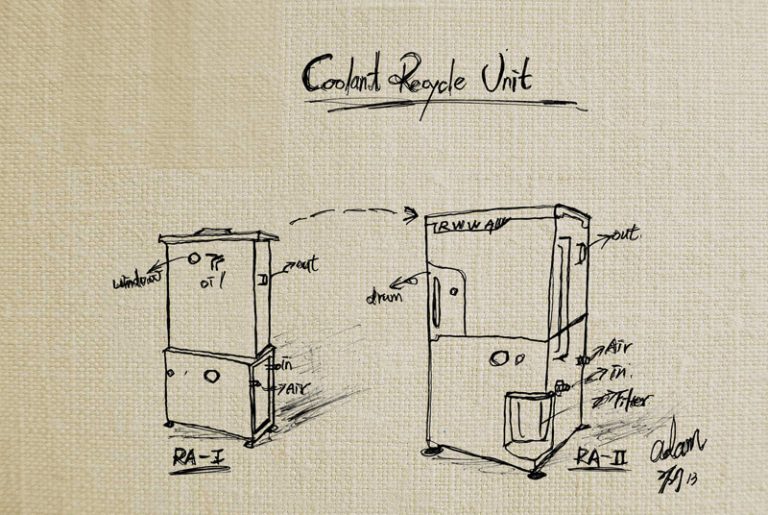

ULTRA SERIES - COOLANT PURIFICATION SYSTEMS

| Ultra 90 | Ultra 360 | |

|---|---|---|

| Dimensions L X W X H (mm) | 300 X 390 X 430 | 220 X 410 X 720 |

| Flow Rate (litres/h) | 90 | 360 |

| Net Weight (kg) | 25.0 | 28.0 |

| Air Pressure Requirement (Bar) | 1.6 | |

PLUG & PLAY - SIMPLE AND EFFECTIVE

- Installation and set up in less than 5 minutes

- Will not incur machine downtime

- No electricity required

- No consumable parts

- Continuous operation

- Will not affect existing coolant concentration

- Compact size

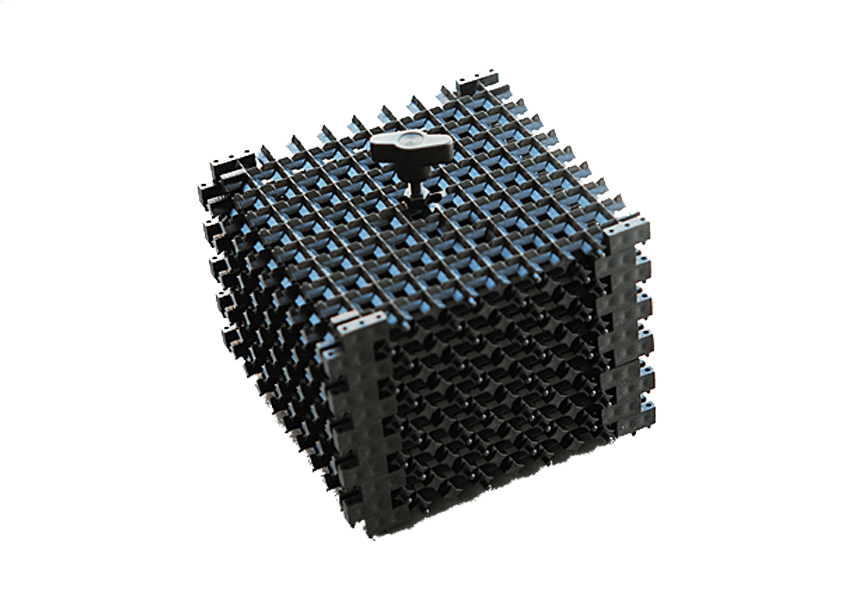

STPM - THE WORKHORSE

A patented design embedded with non-lipophilic material is what allows the rapid separation of oil and coolant/water mix.

Each module consists of multiple filter screens overlapped in a unique design that maximizes the surface contact area. This enhances the oil separation process, increasing coolant life by up to 5 times and tool life improvement by 20 – 40%.

INSTANT RESULTS

GreenEcoPro’s Coolant Purification Systems is a practical and inexpensive solution to improve your work environment.

- Cleaner operating environment

- Lower waste disposal costs

- Healthier work conditions

FC SERIES - CHIP REMOVAL SYSTEMS

| FC-180 Plus | FC-380 | |

|---|---|---|

| Dimensions L X W X H (mm) | 760 X 380 X 760 | 990 X 440 X 740 |

| Filter Bucket Capacity (litres) | 17 | 17 |

| Net Weight (kg) | 59.0 | 72.0 |

| Air Pressure Requirement (Bar) | 5.0 | |

| Flow Rate (litres/min) | 180 | 380 |

| Filter Size (um) | 380 (180 option) | |

JUST AS EASY

- No machine downtime

- No electricity required

- No consumables

- Continuous operation

- Compact size

- Great portability

NEGATIVE PRESSURE, POSITIVE IMPACT

Witness quick and effective removal of sludge and chips in the coolant tank.

- Maximize usage of coolant tank

- Increased coolant and tool life

Need more information?

For a no-obiligation on-site demonstration, reach out to us today.